High Precision Machining

We have facilities with world’s most high precision machines with which we can meet your production/assembly/manufacturing needs. We are capable to transform your concept, CAD drawings or models to extremely high tolerance machined parts with tolerances as close as 0.002 mm

We can fulfill all your needs of tool room jobs like core and cavity replacement inserts for moulds, high speed injection moulds, die casting dies, punch and dies for press tools, fine blanking tools or high speed stamping tools. We have some of the most experienced toolmakers and machinists in our facilities and we can stretch the boundaries of possibility to achieve your high tolerance needs with machineries like high precision CNC machines including

- 5-axis machining centers

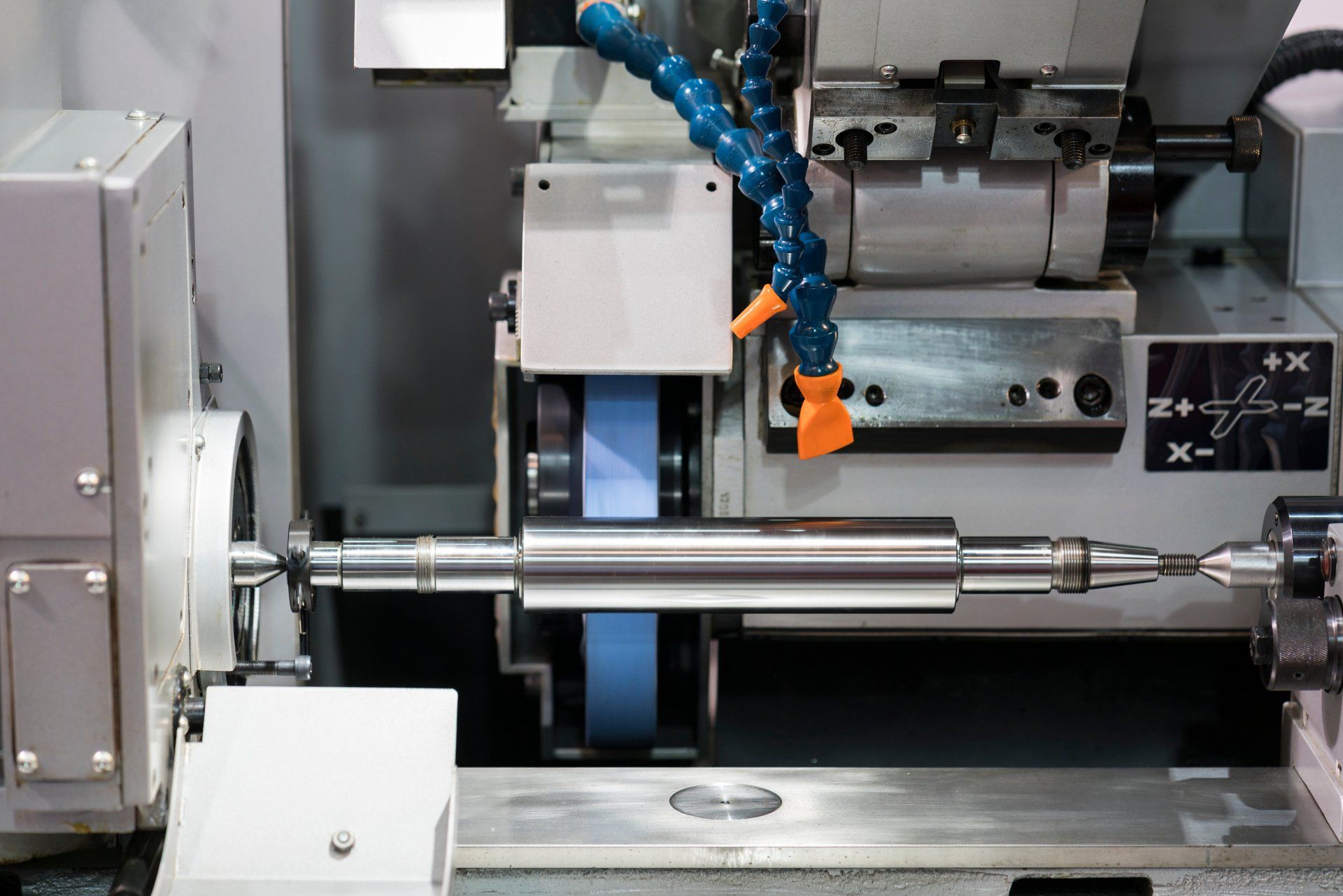

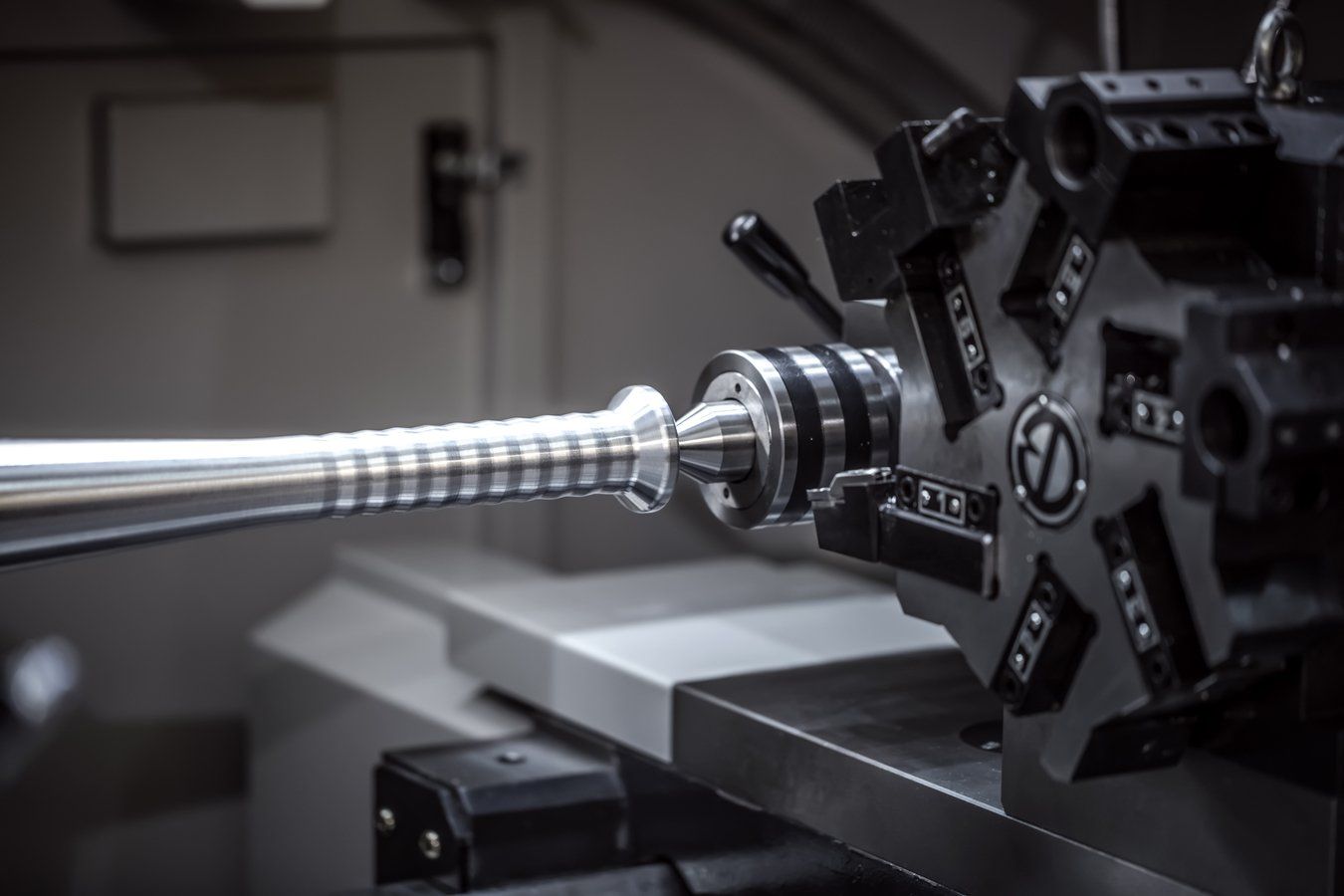

- CNC milling, CNC lathe

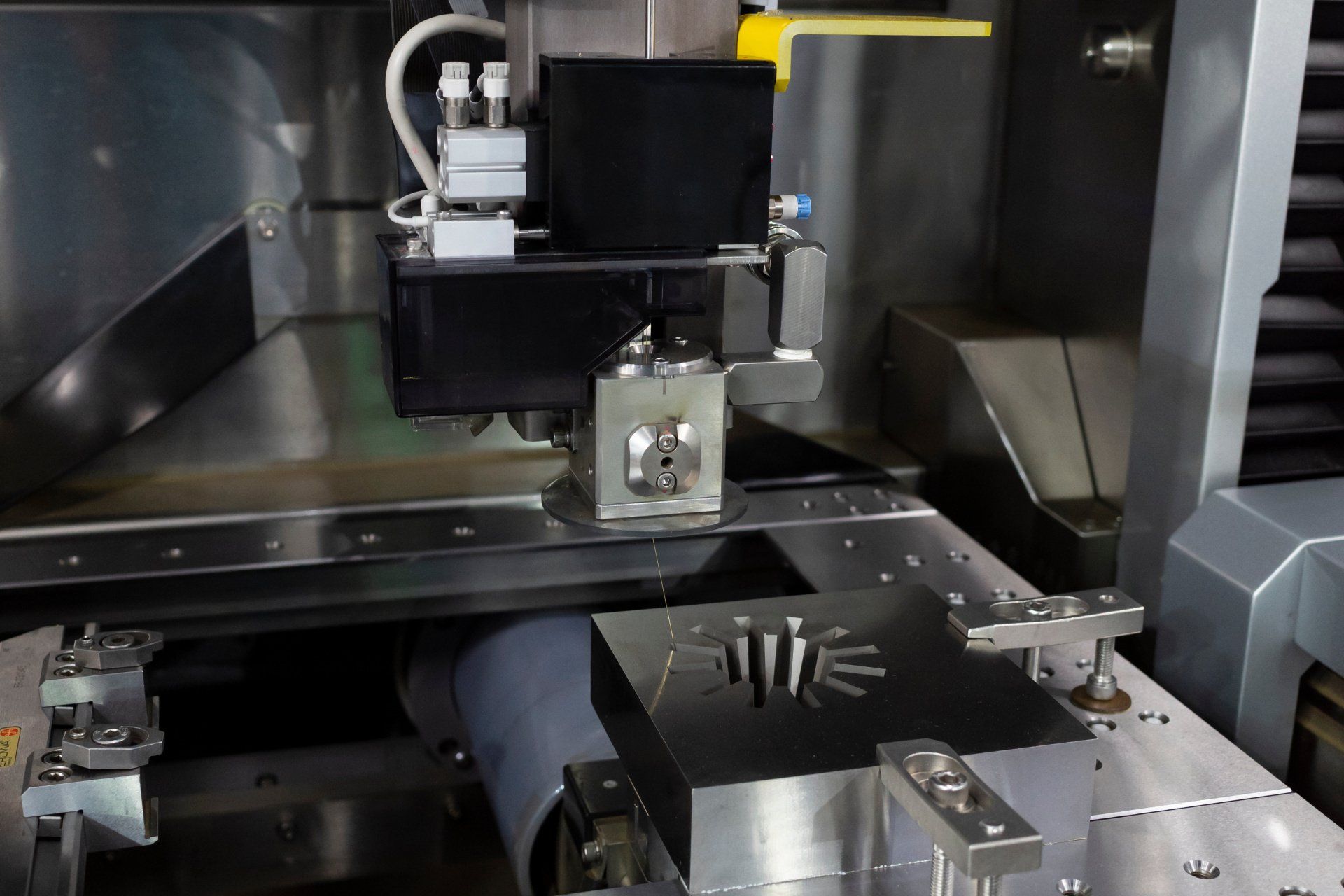

- Wire EDM (up to 0.1mm wire dia)

- Spark erosion machines with orbiting capabilities (Ram EDM)

- Surface grinding

- Cylindrical grinding

- Jig grinding

- Profile grinding

OUR MANUFACTRING IS POWERED WITH CIMATRON 16

Please talk to us, so that our technical consultant can perform onsite consultation for you. We can do a detail need analysis of your requirements including dimensions, tolerances and fitments to make sure that we make machining parts to satisfy your needs. We can discuss with you the machining possibilities and also we can provide you a detailed critical dimension inspection report and material hardness test results along with the delivery of parts. Our metrology department has modern inspection equipment like coordinate measuring machine (CMM), measuring microscope and profile projectors. With these facilities we can take measurements at sub-micron-levels to ensure minimal dimensional error.

We also can provide you CNC mass production jobs like brass inserts for fittings or for over moulding, mass production parts or special fasteners to suits to medical or aerospace industries. We deal with machining in metals like Super alloys, Medical grade stainless, titanium, Hastelloy®, nimonics, Monel®, Inconel®, tungsten carbide, aluminium alloys, copper, etc.